山东理工大学机械工程学院导师:程祥

山东理工大学机械工程学院导师:程祥内容如下,更多考研资讯请关注我们网站的更新!敬请收藏本站,或下载我们的考研派APP和考研派微信公众号(里面有非常多的免费考研资源可以领取,有各种考研问题,也可直接加我们网站上的研究生学姐微信,全程免费答疑,助各位考研一臂之力,争取早日考上理想中的研究生院校。)

微信,为你答疑,送资源

山东理工大学机械工程学院导师:程祥 正文

姓名:程祥

电话:681039

职称:教授

邮箱:happychengx@aliyun.com

个人基本情况

1. 2010.10-至 今 山东理工大学,机械工程学院,副教授 / 教授

2. 2006.10-2010.09 美国加州大学戴维斯分校,机械与航空工程系,博士后

3. 2002.09-2006.04 西安理工大学,机械制造及其自动化,博士

4. 1999.09-2002.07 西安理工大学,机械制造及其自动化,硕士

5. 1995.09-1999.07 西安理工大学,机械制造及其自动化,学士

主要研究方向

1. 超精密微细铣削技术与装备(在读研究生4名);

2. 人工骨3D打印与铣削复合加工技术与装备(在读研究生1名);

3. 精密高效硬脆性材料加工技术(在读研究生1名:Hisham Manea);

4. 智能关节型机械手(在读研究生1名)。

【已培养毕业研究生:代玉娟,张升,国宪孟,李元镇,孟繁杰,刘肖肖,吕福顺,孙秋莲,王飞】

【在读研究生:杨学明,王文豪,李阳,高希坤,Hisham Manea,宋少康,韩宗旺】

开设课程

《金属切削原理与刀具》,《先进制造技术》,《机制专业英语》,《学科导论》,《新生研讨课》,《精密和超精密加工技术》研究生双语课

近年的科研项目、专著与论文、专利、获奖

一、近年的科研项目:

【主持】:国家重点研发计划“制造基础技术与关键部件”专项子项目、教育部归国博士启动基金、山东省重点研发计划项目、山东省自然科学基金项目等纵向、横向科研项目18项;

【参与】:省部级以上科研项目13项。

二、主要荣誉奖励:

共获得科技奖励10项。

其中,【以第一完成人】在亚微米级微细铣削装备的设计与开发技术、超硬微细刀具设计与开发技术、微细铣削数学建模与工艺优化技术等方面的研究成果,获得山东省科学技术奖、中国机械工业科学技术奖等省部级奖励4项。

三、【以首位发明人】已授权发明专利:

1. 对称支撑回转工具头,ZL201710120068.7

2. 内支撑回转工具头, ZL201710120211.2

3. 外支撑回转工具头,ZL201710120200.4

4. 外锥面支撑回转工具装置,ZL201710120111.X

5. 无心支撑回转工具装置,ZL201710120198.0

6. 内锥面支撑回转工具装置,ZL201710120113.9

7. 双锥面支撑回转工具装置,ZL201710120105.4

8. 桌面三轴龙门式微细加工机床,ZL201310298127.1

9. 姿态微调整装置,ZL201310302306.8

10. 小型双功能特种微细加工机床,ZL201310298197.7

11. 微细螺旋锥形球头铣刀,ZL201110283900.8

12. 小型螺旋刃球头铣刀,ZL201110283892.7

13. 微细锥形球头铣刀,ZL201110284119.2

14. 小型精加工用球头铣刀,ZL201110284906.7

15. 小型球头铣刀,ZL201110283895.0

四、近年来主要发表论文:

1. Xiang Cheng, Xi Zhang, Yebing Tian, Guangming Zheng, Xianhai Yang, Study on micro helical milling of small holes with flat end mills, International Journal of Advanced Manufacturing Technology, 2018, 97: 3119-3128(SCI: 000436813500116)

2. Xiang Cheng, Jiancheng Liu, Guangming Zheng, Xianhai Yang, Yebing Tian, Study of microcutting fundamentals for peripheral and end cutting edges in micro-end-milling, Journal of Micromechanics and Microengineering, 2018, 28: 015011, (SCI: 000417990400001)

3. Xiang Cheng, Li Li, Yumei Huang, Xianhai Yang, Shuangjie Zhou, Theoretical modeling of the critical conditions for ductile-regime milling of single crystalline silicon, Proceedings of the Institution of Mechanical Engineering Part C: Journal of Mechanical Engineering Science, 2015,229(8): 1462-1469 (SCI:000357531000009)

4. X. Cheng, X.T. Wei, X.H. Yang, Y.B. Guo, Unified criterion for brittle-ductile transition in mechanical microcutting of brittle materials, Journal of Manufacturing Science and Engineering, Transactions of the ASME, 2014, 136(5):051013-1-8 (SCI:000341978200014)

5. X. Cheng, X.H. Yang, G.M. Zheng, Y.M. Huang, L. Li, Fabrication accuracy analysis of micromilling tools with complicated geometries by wire EDM, Journal of Mechanical Science and Technology, 2014,28(6):2329-2335 (SCI:000338119100036)

6. X. Cheng, X.H. Yang, Y.M. Huang, G.M. Zheng, Li Li, Helical surface creation by wire electrical discharge machining for micro tools,Robotics and Computer-Integrated Manufacturing, 2014, 30(3):287-294 (SCI:000330335500006)

7. Xiang Cheng, Li Li, Yumei Huang, Shuangjie Zhou, Xianhai Yang, Junying Liu,Study on the error distribution and key parameters for a desktop multi-axis micro milling machine tool, International Journal of Advanced Manufacturing Technology, 2013, 67(9-12):2521-2527(SCI:000322326300046)

8. Xiang Cheng, Yumei Huang, Shuangjie Zhou, Junying Liu, Xianhai Yang, Study on the generative design method and error budget of a novel desktop multi-axis laser machine for micro tool fabrications, International Journal of Advanced Manufacturing Technology,2012, 60(5):545-552.(SCI: 000304097500013)

9. Cheng X., Liu J.C., Zheng G.M., Study on the high-precision shrink-fit holders for micro/nano milling, Advances in Computer Science Research, 2015, 10: 1220-1225. (SCI: 000373134100231)

10. Cheng X., Liu J.C., Zheng G.M., Xu R.F., Study on a desktop machine tool for micromilling, Advances in Computer Science Research, 2015, 10: 1226-1231. (SCI: 000373134100232)

11. X. Cheng, Z.G. Wang, K. Nakamoto, K. Yamazaki, A study on the micro tooling for micro/nano milling, International Journal of Advanced Manufacturing Technology, 2011, 53(5): 523-533 (SCI: 000287754200009)

12. X. Cheng, Z.G. Wang, K. Nakamoto, K. Yamazaki, Design and development of micro straight edge end mills for micronano machining of hard and brittle materials, Journal of Mechanical Science and Technology, 2010,24(11),1-8 (SCI: 000284024100015)

13. X. Cheng, Z.G. Wang, S. Kobayashi, K.Nakamoto, K. Yamazaki, Tool fabrication system for micro/nano milling---Function analysis and design of a six-axis Wire EDM machine, International Journal of Advanced Manufacturing Technology, 2010, 46(1): 179-189, (SCI: 000273470700021)

14. X. Cheng, Z.G. Wang, S. Kobayashi, K.Nakamoto, K. Yamazaki, Development of a computer assistant programming system for micro/nano milling tool fabrication by multi-axis Wire EDM, International Journal of Computer Integrated Manufacturing, 2009, 22(9), 847-856,(SCI: 000269658700003)

15. X. Cheng, Z.G. Wang, S. Kobayashi, K.Nakamoto, K. Yamazaki, Development of a six-axis wire electrical discharge machining machine for the fabrication of micro end mills, J. Engineering Manufacture, 2009, 223(2), 121-131,( SCI: 000264223700001)

16. X. Cheng, K. Nakamoto, M. Sugai, S. Matsumoto, Z.G. Wang, K. Yamazaki, Development of ultra-precision machining system with unique wire EDM tool fabrication system for micro/nano-machining, CIRP Annals -Manufacturing Technology (2008) , Volume 57, Issue 1, 2008, pp. 415-420, ( SCI: 000257153300100)

17. X. Cheng, Z.G. Wang, K. Nakamoto, K. Yamazaki, Design and development of micro polycrystalline ball end mill for micro/nano freeform machining of hard and brittle materials, J. Micromech. Microeng. 19 (2009) 115022, (SCI: 000270967800023)

18. Fei Wang, Xiang Cheng, Qianjian Guo, Xianhai Yang, Guangming Zheng, Experimental study on micromilling of thin walls, Journal of Micromechanics and Microengineering, 2018, 29: 015009, (SCI: 000452479600003)

19. X. Cheng, X.H. Yang, G.M. Zheng, R.F. Xu, L. Li, Study on the sticking materials on tools in micromilling of single crystalline silicon, International Journal of Manufacturing and Management, 2017, 31(5): 460-471. (EI: 20181004852136)

20. X. Cheng, H.Y. Liu, X.G. Yang, Y.M. Huang, G.M. Zheng, Study on the design techniques for energy-saving miniaturized machine tools for micromachining, Energy Education Science and Technology Part A: Energy Science and Research, 2014, 32(5): 3173-3182 (EI: 20150700516005)

21. Xiang Cheng, Xi Zhang, Junying Liu, Xianhai Yang, Zhongqiang Tian, Custom micro tooling for mechanical ductile-mode micro/nano machining of hard and brittle materials, Advanced Materials Research, 2012, 426: 20-23. (EI: 20120514722053)

22. Fei Wang, Xiang Cheng, Yuanyong Liu, Xianhai Yang, Fanjie Meng, Micromilling Simulation for the Hard-to-cut Material, Procedia Engineering 2017, 174: 693-699(EI:20171403543160)

23. Qiulian Sun, Xiang Cheng, Yuanyong Liu, Xianhai Yang, Yuanzhen Liu, Modeling and Simulation for Micromilling Mechanisms, Procedia Engineering 2017, 174: 760-766(EI:20171403543230)

24. Xiang Cheng, Xianhai Yang, Li Li, Junying Liu, Design of a three-axis desktop micro milling machine tool, 12th Conference on Machining and Advanced Manufacturing Technology, CMAMT 2013,2013.7.24-27,厦门, 735-739. (EI:20135117092570)

25. Cheng Xiang, Gao Bin, Liu Junying, Yang Xianhai, Study on the ductile-mode milling of brittle ceramics, 2nd International Conference on Mechatronics and Intelligent Materials, 2012.5.18-19, 桂林,3654-3657.( EI: 20121414924325)

26. Xiang Cheng, Junying Liu, Xianhai Yang, Zhongqiang Tian, Peng Jia, Study on the dedicated CAD sub-system for custom tooling, International Conference on Civil Engineering and Building Materials, 2011.7.29-31,昆明, 1930-1933. (EI: 20112714114187)

27. Xiang Cheng, Xi Zhang, Junying Liu, Zhongqiang Tian, Study on the preparation process for high accuracy micro machining by wire electrical discharge machining, 2011 International Conference on Computational Materials Science , 2011.4.17-18, 广州, 56-60. (EI: 20112914166252)

28. X. Cheng, Y.M. Huang, Workspace Generation of The 3-PRS parallel robot based on the NN, , The First International Conference on Machine Learning and Cybernetics (ICMLC 2002, Nov. 3-7), Beijing,China, Vol. 1-4: 2087-2089 (EI: 2003127407130)

29. X. Cheng, Y.M. Huang, Study on kinematic characteristics and singularities of a 3 dof parallel robot, The third International Conference on Machine Learning and Cybernetics (ICMLC 2004, Aug. 26-29), Shanghai,China, 2870-2873(EI: 2004458446951)

30. 程祥,李丽,黄玉美,杨先海,刘军营,多轴微细铣削机床的精度设计方法研究,工程设计学报,2013,20(2):102-106

31. 程祥,杨先海,高斌,刘军营,田忠强,微细塑性铣削单晶硅实验研究,山东理工大学学报,2012,26(4):53-60

32. 吕福顺,程祥,刘肖肖,郑光明,杨先海,PEEK的3D打印参数优化及铣削试验研究,组合机床与自动化加工技术,2018,3(3): 38-44

33. 孙秋莲,程祥,田业冰,郑光明,王飞,微沟槽顶部毛刺宽度微细切削试验研究,组合机床与自动化加工技术,2018,8:53-56

34. 孙秋莲,程祥,杨先海,郑光明,刘原勇,赵国勇,微细铣削力对毛刺尺寸的影响规律研究,工具技术,2018,52(5):42-46

35. 王飞,程祥,杨先海,郑光明,刘原勇,赵国勇,微型薄壁件的微细铣削机理与工艺研究,组合机床与自动化加工技术,2018,7:160-173

36. 孟繁杰,程祥,李元镇,杨先海,PMMA微细铣削实验工艺研究,机械设计与制造,2017,2:101-104

37. 刘肖肖,吕福顺,刘原勇,程祥,杨先海,一种增材与减材复合制造机研究,制造技术与机床,2017,10:49-52.

38. 吕福顺,刘肖肖,程祥,郑光明,杨先海,基于FDM的3D打印参数优化实验研究,组合机床与自动化加工技术,2017,9:114-121

39. 李元镇,程祥,孟繁杰,郑光明,徐汝锋,PMMA微细铣削参数优化实验研究,制造技术与机床,2016(2):21-26

40. 国宪孟,程祥,张升,李贺,曾令国,基于Abaqus的正交切削仿真的有限元分析,机床与液压,2015,43(13):134-141

41. 张升,程祥,微细铣削工艺参数优化实验研究,机械设计与制造,2014,5(1):91-94

42. 代玉娟,程祥,杨先海,张升,微细切削性能有限元仿真分析,计算机仿真,2014,31(3):243-247

43. 张升,程祥,杨先海,代玉娟,超精密桌面微细铣削机床的研制,机械设计与制造,2014,1(1):110-112

44. 李贺,程祥,曾令国,基于nRF24L01芯片的进程无线通讯系统设计,现代电子技术,2014,37(15):32-34

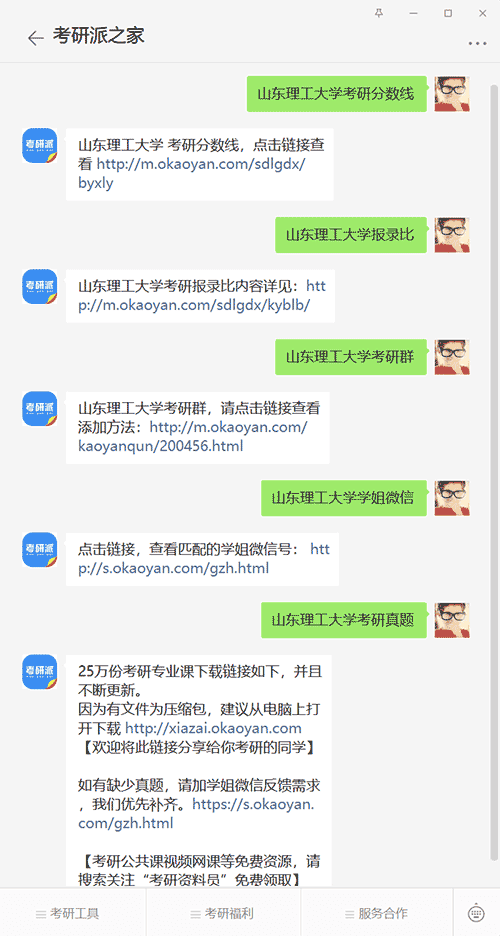

添加山东理工大学学姐微信,或微信搜索公众号“考研派小站”,关注[考研派小站]微信公众号,在考研派小站微信号输入[山东理工大学考研分数线、山东理工大学报录比、山东理工大学考研群、山东理工大学学姐微信、山东理工大学考研真题、山东理工大学专业目录、山东理工大学排名、山东理工大学保研、山东理工大学公众号、山东理工大学研究生招生)]即可在手机上查看相对应山东理工大学考研信息或资源。

山东理工大学

本文来源:http://www.okaoyan.com/sdlgdx/yjsds_518036.html

推荐阅读

-

山东理工大学机械工程学院导师:殷凤仕

姓名殷凤仕性别男民族汉出生年月政治面貌无党派职称教授职务教师办公电话学习工作经历山东大学(原山东工业大学)材料科学与工程学院本科、硕士;毕业于中国科学院金属研究所,博士;至……

日期:11-16 阅读量:20 -

山东理工大学机械工程学院导师:赵婷婷

姓名赵婷婷性别女民族汉出生年月政治面貌群众职称教授职务教师办公电话学习工作经历年年山东工学院锻压工艺与设备专业本科年年山东博山锻压厂技术员年年山东工业大学压力加工专业硕士研……

日期:11-16 阅读量:20 -

山东理工大学机械工程学院导师:朱光明

姓名朱光明性别男民族汉出生年月政治面貌中共党员职称副教授职务无办公电话学习工作经历燕山大学机械制造及其自动化专业读本科燕山大学机械设计及理论专业读博士上海交通大学机械工程博……

日期:11-16 阅读量:20 -

山东理工大学机械工程学院导师:方晓英

姓名方晓英性别女民族汉照片出生年月政治面貌群众职称副教授职务教师办公电话学习工作经历学习经历:就读鞍山钢铁学院(现辽宁科技大学)金属压力加工专业并获学士学位;就读东北大学材……

日期:11-16 阅读量:20 -

山东理工大学机械工程学院导师:韩明

姓名韩明性别男民族汉出生年月政治面貌中共党员职称教授职务无办公电话无学习工作经历天津大学材料科学与工程系金相专业,本科天津大学材料科学与工程系金相专业,硕士浙江大学材料科学……

日期:11-16 阅读量:20 -

山东理工大学机械工程学院导师:张勇

姓名张勇性别男民族汉出生年月政治面貌中共党员职称教授职务办公电话学习工作经历年年,合肥工业大学铸造专业本科;年年,东南大学铸造专业硕士研究生;年年,东南大学铸造专业博士研究……

日期:11-16 阅读量:20 -

山东理工大学机械工程学院导师:盛文斌

姓名盛文斌性别男民族汉族出生年月年月政治面貌中共党员职称副教授职务院长助理办公电话学习工作经历年,在哈尔滨工业大学获得学士、硕士和博士学位,年进入中科院金属研究所博士后流动……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:李家亮

李家亮,男,年月出生副教授,工学博士。近年来,主要从事环保化工、精细化工、无机非金属材料等领域的研究工作,主持并承担各类各级科研项目余项,参与国家项目、国家自然科学基金项目……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:柳玉英

柳玉英女,年生,教授,硕士生导师。年月毕业于山东师范大学化学系,获理学学士学位。年月毕业于东北大学分析冶金分析专业,获工学硕士学位。年晋升讲师,年晋升副教授,年晋升教授。年……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:孟波

孟波女,年生,教授,硕士生导师。年月毕业于哈尔滨师范大学化学系;年在吉林农业大学土壤化学系工作;年在东北大学化学系读研究生;年在东北大学化学系教书;年底调入山东理工大学。年……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:赵剑英

姓名:赵剑英,性别:女;出生年月:;学位:博士;职称:副教授;电话:;教育背景:本科:高分子化学与物理,南开大学化学系,硕士:高分子化学与物理,南开大学化学系,;博士:有机……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:赵增典

赵增典男、生、聘为教授、化学工程学院副院长、硕士生导师、年山东师范大学化学教育专业本科毕业,年南京工业大学化学工程专业在职硕士毕业。学术简历自年本科毕业到理工大学工作以来,……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:周子彦

周子彦男,年生,博士,教授,硕士生导师。年月于东北师范大学化学专业本科毕业,年月于延边大学获博士学位。年晋升讲师,年晋升副教授,年晋升教授。年聘为硕士生导师。主要科研项目:……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:陈克勋

陈克勋,男,年生,副教授,硕士生导师。年毕业于合肥工业大学高分子科学与工程专业,获学士学位;年毕业于湖北省化学研究院应用化学专业,获硕士学位;年毕业于中国科学技术大学高分子……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:李忠芳

李忠芳,男,年生:博士,教授,硕士生导师。年月毕业于天津大学化工学院化学工程专业,获工学博士学位。年毕业于东北师范大学化学系有机化学专业,获理学硕士学位。年毕业于山东师范大……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:王桂强

王桂强,男,理学博士,副教授。年毕业于青岛科技大学材料学,获工学硕士学位。年毕业于中科院化学所物理化学,获理学博士学位。主要从事功能高分子及新型光功能材料的研究。主要讲授课……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:王粤博

王粤博,性别:女出生年月:年月职称及任职时间:副教授,硕士生导师年月进入我校任教,年月在南京大学获得理学博士学位,年月在南京大学获得理学博士学位。教学、科研、课题情况及指导……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:邢伟

邢伟男,年月出生,博士,副教授。享受山东理工大学特殊津贴,从事多孔炭材料的制备及在吸附、电化学储能等领域的应用基础研究。年月获中国石油大学(华东)工学博士学位。博士学位论文……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:于元章

于元章,男,年生。硕士,教授,硕士生导师。年月于山东大学高分子化学专业本科毕业,毕业后到核工业部北京第五研究所工作,任助理工程师。年月于山东大学获得硕士学位,毕业后到中石化……

日期:11-16 阅读量:20 -

山东理工大学化学工程学院导师:毕玉遂

毕玉遂:教授,男,中共党员,硕士生导师,化工专家,第四届、五届市专业技术拔尖人才。长期从事有机化学、有机合成化学和精细化学品化学的教学和科研工作,以不断改革创新的教育思想和……

日期:11-16 阅读量:20